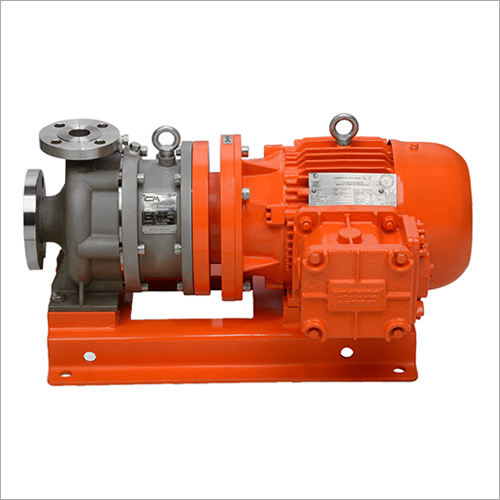

SS Magnetic Drive Chemical Process Close Coupled Pump

Product Details:

- Flow Rate max. 100m3/h

- Usage Pharmaceutical Industry, Chemical Industry

- Product Type Close Coupled Pump

- Material Stainless Steel

- Suction Type Flooded suction

- Click to View more

SS Magnetic Drive Chemical Process Close Coupled Pump Price And Quantity

- 150000.00 INR/Piece

- 1 Piece

SS Magnetic Drive Chemical Process Close Coupled Pump Product Specifications

- Stainless Steel

- Pharmaceutical Industry, Chemical Industry

- Flooded suction

- max. 100m3/h

- Close Coupled Pump

SS Magnetic Drive Chemical Process Close Coupled Pump Trade Information

- Cash in Advance (CID)

- 50 Piece Per Month

- 30 Days

- All India

Product Description

For the effective transmission of corrosive chemicals in industrial applications, turn to the SSmagnetic drive chemical process close coupled pump. The pump's strong permanent magnet drive eliminates the need for a mechanical seal, making it safe and dependable. It is built from a sturdy stainless-steel shell. Our offering has a high efficiency motor and has a 19 litres per minute maximum flow rate capacity. It also includes a variety of control capabilities, including programmable temperature, pressure, and speed settings. A dependable and affordable option for the transport of a variety of chemicals is SSmagnetic drive chemical process close coupled pump.

Features

- Single Stage, Horizontal Centrifugal Pump.

- Hydraulic Performance and Dimensions according to DIN EN ISO 2858

- Technical design based on DIN EN ISO 15783

- Permanent Magnet Drive

- Maintenance Free

- Separation of Liquid Chamber to Atmosphere by Means of Isolation Shell

- Slipless Power Transfer

- Materials : Steel, Stainless Steel, Nickel Based Materials

- Close Coupled Block Design

- Hydraulically balanced impeller for minimum bearing loads

- Product-Lubricated Journal Bearings; made of Silicon Carbide (SSiC) or Customized Materials

Operation Range

- Flow Rate : max. 100m /h3

- Delivery Head : max. 100 metre

- Pressure Rating : Class 150

- Temperatures : -35 degree C to +250 degree C

- Kinematic viscosities : 0.5 to 350 mm /s

Technical data

Working Principle | Radial flow pump |

Stages | Single stage |

Priming Method | Flooded suction |

Sealing System | Magnetic coupling |

Standards | DIN EN ISO 2858 /ANSI |

Standards | DIN EN ISO 15783 /ANSI |

ATEX | 2014/34/EU |

2 POLE (2900 RPM)

Pump Model |

|

|

|

| ||||||||||||||||

|

|

| impeller | Q | H | Pump | Support | Motor | ||||||||||||

a | f | h1 | h2 | h3 | m1 | m2 | m3 | n1 | n2 | S1 | hp | kw | rpm | amps | ||||||

| 25 | 25 | 125 | 4 | 20 | 82 | 425 | 112 | 142 | 340 | 465 | 405 | 62 | 300 | 270 | 16 | 1 | 0.75 | 2900 | 1.6 |

| 32 | 25 | 125 | 5 | 20 | 82 | 475 | 112 | 142 | 340 | 465 | 405 | 62 | 300 | 270 | 16 | 1.5 | 1.1 | 2900 | 2.3 |

| 32 | 25 | 150 | 5 | 30 | 82 | 475 | 112 | 142 | 340 | 465 | 405 | 62 | 300 | 270 | 16 | 2 | 1.5 | 2900 | 3.1 |

| 50 | 32 | 125 | 12.5 | 20 | 80 | 665 | 112 | 140 | 338 | 604 | 554 | 46 | 338 | 308 | 16 | 3/5 | 2.2/3.7 | 2900 | 4.3/7 |

| 50 | 32 | 160 | 12.5 | 32 | 80 | 665 | 132 | 160 | 604 | 554 | 46 | 338 | 308 | 16 | 5/7.5 | 3.7/5.5 | 2900 | 7/10 | |

| 50 | 32 | 200 | 12.5 | 50 | 80 | 720 | 160 | 180 | 700 | 675 | 50 | 350 | 320 | 16 | 10/12.5 | 7.5/9.3 | 2900 | 13.7/16.5 | |

| 50 | 32 | 250 | 12.5 | 80 | 100 | 800 | 180 | 225 | 490 | 700 | 675 | 50 | 400 | 370 | 16 | 15/20 | 11/15 | 2900 | 19.3/26 |

| 65 | 40 | 125 | 25 | 20 | 80 | 665 | 112 | 140 | 338 | 604 | 554 | 46 | 338 | 308 | 16 | 5/7.5 | 3.7/5.5 | 2900 | 7/10 |

| 65 | 40 | 160 | 25 | 32 | 80 | 665 | 132 | 160 | 380 | 604 | 554 | 46 | 338 | 308 | 16 | 7.5/10 | 5.5/7.5 | 2900 | 10/13.7 |

| 65 | 40 | 200 | 25 | 50 | 100 | 800 | 160 | 180 | 430 | 700 | 675 | 50 | 350 | 320 | 16 | 12.5/15 | 9.3/11 | 2900 | 16.5/19.3 |

| 65 | 40 | 250 | 25 | 80 | 100 | 850 | 180 | 225 | 500 | 750 | 700 | 50 | 450 | 410 | 16 | 20/30 | 15/22.5 | 2900 | 26/37.5/ |

| 80 | 50 | 125 | 50 | 20 | 100 | 700 | 132 | 160 | 380 | 650 | 600 | 50 | 338 | 308 | 16 | 7.5/10 | 5.5/7.5 | 2900 | 10/13.7 |

| 80 | 50 | 160 | 50 | 32 | 100 | 800 | 160 | 180 | 430 | 650 | 600 | 50 | 338 | 308 | 16 | 12.5/15 | 9.3/11 | 2900 | 16.5/19.3 |

| 80 | 50 | 200 | 50 | 50 | 100 | 900 | 160 | 200 | 470 | 750 | 700 | 50 | 450 | 410 | 16 | 20/30 | 15/22.5 | 2900 | 26/37.5 |

4 POLE (1450 RPM)

Pump Model |

| Nominal duty point |

|

| ||||||||||||||||

|

|

| impeller | Q | H | Pump | Support | Motor | ||||||||||||

a | f | h1 | h2 | h3 | m1 | m2 | m3 | n1 | n2 | S1 | hp | kw | rpm |

| ||||||

| 25 | 25 | 125 | 2 | 5 | 82 | 400 | 112 | 142 | 340 | 440 | 400 | 62 | 300 | 270 | 16 | 0.25 | 0.18 | 1450 | 0.56 |

| 32 | 25 | 125 | 3 | 5 | 82 | 400 | 112 | 142 | 340 | 440 | 400 | 62 | 300 | 270 | 16 | 0.25 | 0.18 | 1450 | 0.56 |

| 32 | 25 | 150 | 3 | 10 | 82 | 450 | 112 | 142 | 340 | 440 | 400 | 62 | 300 | 270 | 16 | 0.5 | 0.37 | 1450 | 1 |

| 50 | 32 | 125 | 6.3 | 5 | 80 | 600 | 112 | 140 | 338 | 580 | 530 | 46 | 338 | 308 | 16 | 0.5 | 0.37 | 1450 | 1 |

| 50 | 32 | 160 | 6.3 | 8 | 80 | 600 | 132 | 160 | 380 | 580 | 530 | 46 | 338 | 308 | 16 | 1 | 0.75 | 1450 | 1.7 |

| 50 | 32 | 200 | 6.3 | 12.5 | 100 | 600 | 160 | 180 | 430 | 650 | 600 | 50 | 350 | 320 | 16 | 1.5 | 1.1 | 1450 | 2.4 |

| 50 | 32 | 250 | 6.3 | 20 | 100 | 650 | 180 | 225 | 490 | 650 | 600 | 50 | 400 | 370 | 16 | 3 | 2.2 | 1450 | 4.3 |

| 65 | 40 | 125 | 12.5 | 5 | 80 | 600 | 112 | 140 | 338 | 580 | 530 | 46 | 338 | 308 | 16 | 1 | 0.75 | 1450 | 1.7 |

| 65 | 40 | 160 | 12.5 | 8 | 80 | 600 | 132 | 160 | 380 | 580 | 530 | 46 | 338 | 30 | 16 | 1.5 | 1.1 | 1450 | 2.4 |

| 65 | 40 | 200 | 12.5 | 12.5 | 100 | 600 | 160 | 180 | 430 | 650 | 600 | 50 | 350 | 320 | 16 | 2 | 1.5 | 1450 | 3 |

| 65 | 40 | 250 | 12.5 | 20 | 100 | 650 | 180 | 225 | 500 | 650 | 600 | 50 | 450 | 410 | 16 | 4 | 3 | 1450 | 7.8 |

| 80 | 50 | 125 | 25 | 5 | 100 | 650 | 132 | 160 | 380 | 580 | 530 | 50 | 338 | 308 | 16 | 1.5 | 1.1 | 1450 | 2.4 |

| 80 | 50 | 160 | 25 | 8 | 100 | 700 | 160 | 180 | 430 | 580 | 530 | 50 | 338 | 308 | 16 | 2 | 1.5 | 1450 | 3 |

| 80 | 50 | 200 | 25 | 12.5 | 100 | 750 | 160 | 200 | 470 | 650 | 600 | 50 | 450 | 410 | 16 | 4 | 3 | 1450 | 7.8 |